Blog

Auto repair shop advice

Recruiting? Here’s What Auto Technicians Are Looking For

Recruiting and hiring technicians is still one of the most challenging issues facing auto repair shops. At least, that’s what we continue to hear from our customers. In order to recruit talented techs it helps to understand what is...

Facebook Messenger Scams Targeting Auto Repair Shops

We are hearing from customers and seeing on multiple news sources that there has been a significant uptick in the number of Facebook and Instagram Messenger scams and cyber attacks over the past three to six months. Here’s the damage...

The Challenge of Finding & Keeping Motivated Technicians

If you had to choose between a day where half of your customers didn't show up or a day where half of your staff didn't, which would you pick? For most shops, the second scenario is much scarier. The struggle to secure motivated...

Do Online Directory Listings Matter for Auto Repair Shops?

What are online directory listings? Online directory listings (also known as citations) are the backbone network of local businesses on the web. Google, Facebook, Bing and Yelp are some of the more well-known online directories. As an...

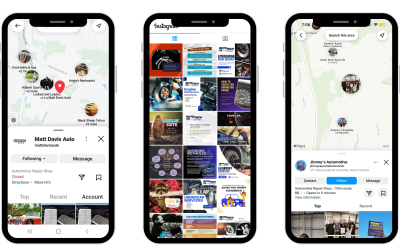

Instagram Is Now a Necessity for Auto Repair Shops

If your auto repair shop is currently not using Instagram, now is the time to do so. Instagram has updated their map functionality to make it easier for users to discover local businesses. Thinking about joining Instagram? Well now is the...

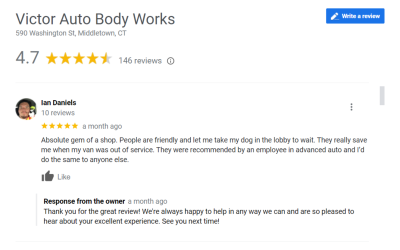

Should I Respond to My Auto Repair Shop Google Reviews?

The short answer is yes, but there’s more to it than just posting a quick response. That’s especially true if the review is negative. I’m writing this blog because we’ve seen a lot of unprofessional responses to negative reviews lately....

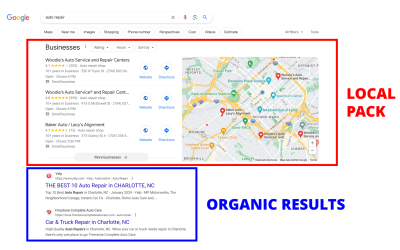

How Do Consumers Search for Auto Repair Shops Online?

There is a lot of confusion among auto repair shop owners about how consumers search for auto repair services on the web. Our goal in this blog is to clear up the confusion and help you understand how most consumers search for auto repair...

Benefits of Allowing Customers to Schedule Online

Most of the repair shop owners we talk to either love the idea of allowing customers to schedule real appointments online…or they absolutely hate it. The resistance is understandable. It’s difficult to manage a shop’s schedule with cars,...

Local Search: 4 Tactics to Elevate Your Auto Repair Shop

The four local search tactics are: Get a consistent flow of Google Reviews Make sure you have a dedicated page on your website for each service or service category that you offer Get links from other locally-relevant websites to your...